Advantages and Disadvantages of Jaw Crusher

2023年9月24日 Advantages of jaw crusher. Simple structure: Due to its simple structure, the jaw crusher is relatively simple to operate and maintain, which greatly reduces the user’s work intensity.

learn more

Jaw Crusher VS Cone Crusher Advantages and

Jaw crusher main advantages: simple structure, low manufacturing cost, convenient maintenance, reliable work, small machine height, easy to

learn more

Jaw Crusher Advantages and Disadvantages - maden

In this article, we will discuss the advantages and disadvantages of jaw crushers, shedding light on their overall impact on industrial operations. Jaw Crusher Advantages: jaw

learn more

Gyratory VS Jaw Crushers: Advantages

2016年2月28日 The jaw crusher, because of its box-frame construction, and simple toggle mechanism, is especially well adapted to extra heavy

learn more

Jaw Crusher VS Cone Crusher (A Comparison From 7 Points)

2023年5月27日 When choosing a stone crusher, knowing the seven differences between a cone crusher and a jaw crusher can help us make the right decision. But that is not

learn more

Unique advantages of jaw crusher-SBM Industrial

2018年9月7日 The unique advantages of jaw crusher are: 1, the crushing chamber is deep and no dead zone, which improves the feeding capacity and output. 2, its crushing ratio

learn more

What are the advantages of jaw crusher

2023年3月21日 Because jaw crusher adopts the mode of combining motor and crusher, it occupies less space than other crusher, and can work in various harsh environments.

learn more

What is the role of 'jaw crusher' in the construction industry ...

2023年9月30日 Importance in the Construction Industry. Applications of Jaw Crushers in Construction. Jaw Crusher Working Principle: Unlocking the Secrets of Efficiency.

learn more

Advantages and disadvantages of jaw crusher and cone crusher

2023年9月8日 1. High Reduction Ratio: Jaw crushers have a large reduction ratio, which means that they can handle larger pieces of materials and produce finer output. This

learn more

What Are The Pros And Cons Of Jaw Crushers? - Mormak

Advantages. Jaw crushers tend to be highly versatile machines and are therefore often the crusher of choice for a wide variety of applications. Generally speaking, jaw crushers are

learn more

Jaw Crusher - an overview ScienceDirect Topics

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. The capacity is primarily a function of: 1. crusher design characteristics such as width and depth of the crushing chamber, 2.

learn more

Jaw Crusher: What Is It How Does It Work?

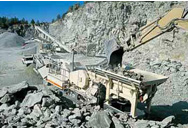

2024年5月9日 A jaw crusher is a machine that breaks down large rocks into smaller pieces of rock, gravel, or dust. It does this by placing two jaw plates perpendicular to each other and squeezing the rock between them

learn more

Jaw Crushers - Crushing Tigers

The Sandvik QJ241 mobile jaw crusher is the most compact machine in the series, and is ideal for smaller operations. ... Sandvik QJ341 Tracked Jaw Crusher. Sandvik QJ341 mobile jaw crusher is the ideal solution for a wide range of applications. It's equipped with a C12 ...

learn more

“Computer Aided Design of Jaw crusher” - 911 Metallurgist

2016年12月19日 1.4 Crusher Size and Power rating: The size of a jaw crusher is usually expressed as gape x width. The common crusher types, sizes and their performance is summarized in Table 1.1.Currently, the dimension of the. largest Blake-type jaw crusher in use is 1600 mm x 2514 mm with motor ratings of 250-300. kW.

learn more

McLanahan Jaw Crushers

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers. On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavy-duty double ...

learn more

Jaw Crusher Diagram: Simplified Guide - JXSC

2024年2月18日 A jaw crusher is an indispensable tool in the mining and construction industries, known for its power to fragment hard materials such as rock and minerals. Comprising type of jaw crusher—the robust Single-toggle and the efficient Double-toggle—these hefty machines operate on the principle of compressing materials between

learn more

Reasons to use jaw crushers – Advantages and Disadvantages

2014年12月29日 The jaw crusher is capable and powerful enough to crush all materials in even size. This crushing machine has the capacity to crush 1-2 tons of material per hour. Easy maintenance – Although heavy-duty and used for complex crushing applications, the jaw crushers are easy to use machines that require simple maintenance for long service

learn more

Hammer Crusher VS Jaw Crusher Which Is Better (7 Tips)

Hammer Crusher is mainly composed of casing, rotor, main shaft, lining plate and striking plate. Hammerhead is the key vulnerable part. Jaw Crusehr is composed of frame, transmission device, adjusting device, tension device, safety device and lubrication system. The jaw plate is the main wearing part. 5. Different Configuration of Production Line.

learn more

What Is A Jaw Crusher? - Caldas Engineering and

A jaw crusher primarily consists of two plates: the fixed jaw plate and the movable jaw plate. The key to its operation is the reciprocating movement of the movable jaw plate, reminiscent of our very own jaw’s motion when we chew. This physical process exerts sufficient force on the input material, often large chunks of rock or ore, causing ...

learn more

Nordberg® C Series™ jaw crushers - Metso

The core of Nordberg® C Series™ jaw crusher is a pinned and bolted, non-welded frame construction that provides excellent fatigue strength. All the frame components are casted using an alloy developed in-house especially for jaw crushers. In addition to solid casting, the crushers’ frame has a cellular, so called honeycomb structure that ...

learn more

Below the surface: Setting up an underground

2014年4月1日 Jaw crushers are the most common solution in underground applications when the throughput is below 1000 tonnes per hour, depending somewhat on the scalping solutions. Above 1000 tph, primary gyratory

learn more

RM J110X Mobile Jaw Crusher RUBBLE MASTER

Crusher unit: Single toggle jaw crusher Single toggle jaw crusher : Drive: Diesel-hydraulic Diesel-hydraulic : Engine: 250kW CAT Tier 4F 335 HP CAT Tier 4F : Feed unit: 6.15 m³ 8 yd³: Feed unit (extended) 12 m³ 15.5 yd³:

learn more

Jaw Crusher Explained - saVRee

For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top i.e. the opening), and each jaw will have a 54-inch width. If a jaw crusher is rated by jaw plate

learn more

Jaw crusher EB FLSmidth

Jaw Crusher EB 16-12 Pro with a capacity range of 400 – 1,200 tph; Jaw Crusher EB 14-11 Pro with a capacity range of 300 – 950 tph; Key benefits. High-performance jaw crushing with great energy saving potential. With our EB series, you benefit from a crushing solution that has high performance and durability in its DNA. We designed every ...

learn more

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER ...

2017年6月30日 Moreover, the wear of the jaw liner profile lowers the crusher performance by affecting the shape and the overall size of the crushed particles [12, 13]. Warping and wear of the jaw plate cause a ...

learn more

Introduction to Jaw Crushers: Understanding the Basics

2023年12月30日 Introduction: In the world of material processing and mining, Jaw Crushers stand as stalwart machines, pivotal in breaking down large rocks into more manageable sizes. One of the leading names in ...

learn more

Popularity Jaw Crusher Advantages and Disadvantages

2020年1月4日 Ratio of the effective width of the feed port of the jaw crusher to the width of the discharge opening . Some jaw crushers, whose discharge size is not determined by the size of the discharge opening. 3 using the average particle size before and after crushing ore, also known as the average broken bit point . 1. Low noise and less dust. 2.

learn more

Choosing the Right Jaw Crusher Size and Capacity for

2023年2月28日 Conclusion. Choosing the right jaw crusher size and capacity is crucial for optimizing crusher performance and achieving maximum productivity and profitability. By considering factors such as feed opening size, nip angle, eccentric shaft speed, stroke length, and operating conditions, operators can determine the optimal size and capacity

learn more

GitHub

avantages et inconvénients de l utilisation de blake jaw crusher. Avantages Grinder Machine. equipment for ball mill a substance to powder.Ball Grinding Machine is a type of grin

learn more