Stone Crusher Plant Design: Best Practices for Efficient

2023年2月28日 Stone crusher plant design is a crucial factor in the efficient operation of the crushing process. The primary goal of plant design is to achieve the desired product

learn more

Crushing and Screening Handbook - AusIMM

2021年6月24日 Whether you need a single crusher, a multi-stage process or a complete plant, we assist you with the right design for the most cost-eff ective crushing process.

learn more

My Plant Planner - Metso

Launch My Plant Planner. Design and simulate a new crushing and screening plant in 3D or test how upgrading your current equipment can improve performance. My Plant Planner

learn more

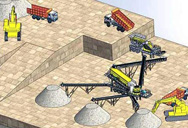

Layout of a four-stage crushing plant for ballast production.

Download scientific diagram Layout of a four-stage crushing plant for ballast production. from publication: Cone Crusher Performance PhD Thesis Cone crushers are used by

learn more

Optimization Capabilities for Crushing Plants - Chalmers

a crushing plant operation consisting of rock size reduction (comminution) and particle size separation (classification) processes. The objective of the crushing plant operation for the

learn more

The Ultimate Guide to Designing an Efficient

2023年2月23日 Designing the layout of an aggregate crushing plant is crucial to ensuring that the plant operates efficiently and effectively. Here are some primary, secondary, and tertiary considerations when designing

learn more

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 For improving the performance parameters of jaw crusher modified design and modeling can be a possible solution. Kinematic analysis and modeling can be used

learn more

Cone Crusher Plant Design - 911 Metallurgist

2017年6月23日 A) Stacked Design. This design is intended to operate in open circuit. With fairly constant ore characteristics and where the feed to the fine crushing plant contains less than 15 percent minus 19MM (¾”) ,

learn more

Crushing Plant Design and Layout Considerations

1 Considerations of stone crusher plant design. The basic purpose of crushing ore is to achieve a certain particle size requirement for ore, raw materials or fuel. In ore dressing, the purpose of crushing ore is: (1)

learn more

CRUSHING PLANT PROCESS OPTIMISATION

2024年5月1日 before the crusher and thereby fed to the crusher again to be re-crushed. Parts of the rock material will thereby pass the crusher more then once. The two types of stages have some fundamental differences that affect the design of the crushing plant both in terms of technical performance and cost of operation.

learn more

Demystifying the Crusher Plant: A Comprehensive Guide to

2024年5月9日 A crushing plant is a one-stop crushing installation, which can be used for rock crushing, garbage crushing, building materials crushing, and other similar operations. Crushing plants may be either fixed or mobile. Useful aggregates from raw materials like stones, rocks, and minerals as their main function. Draw attention to the value of these ...

learn more

Metso NW Series™ Portable crushing screening plants

2018年10月17日 choose from seven different portable plants with GP cones and eight with HPs. If your crushing project requires a portable plant with screen, NW100GPC(S), NW100HPC-CC, NW220GPD, NW200HPD, NW330GPS, NW300HPS and NW96200HPS are equipped with an on-board screen. When needing secondary and tertiary cones for

learn more

How to Design a Crushing Plant - Imagup

2020年12月2日 In general, the effective volume of the hopper design should meet the following two conditions at the same time. No less than the workload of continuous operation of the crusher for 12-15 minutes. The carrying capacity of no less than 3 transport vehicles. 2. The layout of the crushing workshop.

learn more

How to Design a Stone Crusher Plant Layout - LinkedIn

2023年5月11日 Designing a layout. A stone crusher plant designer follows three steps to create the layout: • Process design. • Equipment selection. • Layout. The principal design parameters driving the ...

learn more

Design of a crushing system that improves the crushing

2016年2月10日 gold, iron, and molybdenum ores, may require as much as a tertiary crushing. To design a good crushing plant one has to follow these three steps: crusher selection, crusher layout and process design. 2.4 Crushers . A crusher is a tool or machine that is used to reduce the size of a large solid particle to a smaller solid particle. The

learn more

(PDF) Design and Performance Evaluation of a Stone Crusher

2021年10月7日 The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h with a through-put efficiency of 75.4 %. The crushed products were well graded with 1.89 coefficient of ...

learn more

iron ore crusher plant design step by step

Step 8:Commission the plant. Once the plant is built, it can be commissioned to ensure that it is operating properly. Step 9:Operate the plant. Once the plant is commissioned, it can be operated to produce crushed iron ore. The design of an iron ore crusher plant is a complex process that requires careful consideration of all of the factors ...

learn more

Crushing 101 – Different types of crushers for distinctive needs

2020年12月17日 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

learn more

Crushing and screening plants - stationary, mobile

Metso Nordplant™ is a stationary crushing and screening plant built using pre-designed modules, which allow quick delivery and easy assembly to get your plant up and running in the time you want. Whether you are building

learn more

“Computer Aided Design of Jaw crusher” - 911 Metallurgist

2016年12月19日 opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square. Generally primary jaw crushers have the square opening design, and secondary jaw crushers have rectangular opening design. Jaw crushers are used as primary crushers in a mine or ore processing plant or the first step in the process of reducing rock.

learn more

Crushers - All crusher types for your reduction needs - Metso

The gyratory crusher has no rival in large plants with capacities starting from 1200 t/h and above. To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier. Also, primary gyratories require quite a massive foundation. ... Due to their design, cone crushers are generally a more ...

learn more

Crushing - Metso

The crushers are built to perform with the lowest cost per ton, featuring a unique combination of crusher cavity design, crushing forces, reliability and safety. ... These 2 modular crushing and screening plants are unique, cost-efficient and productive, and designed to provide significant time and resource savings.

learn more

Crushing and Screening Handbook - AusIMM

2021年6月24日 Whether you need a single crusher, a multi-stage process or a complete plant, we assist you with the right design for the most cost-eff ective crushing process. We are the world’s leading supplier of both unit machines and complete aggregates processing systems. Comprehensive process solutions Your system may involve a whole series of

learn more

Crushing it: A Comprehensive Guide to Stone Crusher Plants

2023年2月28日 Introduction: A stone crusher plant is a machine designed to reduce the size of large rocks, eliminate gravel, or rock dust to smaller sizes for various applications. These plants find application in quarrying, mining, construction, and recycling operations. Stone crusher plants consist of several components, including a primary crusher,

learn more

Scientific Methods to Design Crushing and Screening

2016年7月12日 An important point often overlooked by plant design and application people is that the crusher must have an adequate amount of evenly distributed feed. Figure 8 shows the effect of poor and good feed distribution. If the feed is correct, the crusher will have maximum produc- tivity (highest average crushing force) for minimum mechanical stress.

learn more

Crushing Plant - an overview ScienceDirect Topics

Crushing Plant. Crushing plants are characterized by extensive use of conveyors and the energy for transport is a consideration in selecting the type of circuit. ... PC1375 type I crusher is equipped with a special design of 19-mm-thick conveyor belt with high-strength steel wire, which effectively prolongs its service life. Its standard ...

learn more