Ball Mill - RETSCH - powerful grinding and homogenization

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and

learn more

Grinding in Ball Mills: Modeling and Process Control

There are three types of grinding media that are commonly used in ball mills: • steel and other metal balls; • metal cylindrical bodies called cylpebs; • ceramic balls with regular or

learn more

Planetary Ball Mill PM 100 - RETSCH - highest

The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 ml sample material

learn more

Emax - High Energy Ball Mill - Retsch

Application Database. Unique grinding jar geometry. The High Energy Ball Mill Emax combines high-frequency impact, intensive friction, and controlled circular jar movements to a unique and highly effective size reduction

learn more

Grinding - Hosokawa Alpine

Grinding. Reduce product size to a specific fineness. From pre-crushers for the comminution of coarse materials to jet and ball mills for ultra-fine grinding: Hosokawa Alpine offers

learn more

Intelligent optimal control system for ball mill grinding

2017年8月27日 Abstract: Operation aim of ball mill grinding process is to control grinding particle size and circulation load to ball mill into their objective limits respectively, while

learn more

Grinding - KHD Humboldt Wedag

Grinding. Complete grinding solutions. From the roller press to traditional ball and hammer mills and ancillary equipment, we offer both complete, new grinding circuits or upgrades to existing grinding plants.

learn more

Ball Mill (Ball Mills Explained) - saVRee - saVRee

If a ball mill uses little or no water during grinding, it is a ‘dry’ mill. If a ball mill uses water during grinding, it is a ‘wet’ mill. A typical ball mill will have a drum length that is 1 or 1.5 times the drum diameter. Ball mills with a

learn more

_Taurus - Ball Mill - NETZSCH Grinding Dispersing

3 天之前 NETZSCH Ecutec also carries an extensive selection of special grinding media to optimize the performance of the ball mill specific to the customer's requirements. Together with NETZSCH Ecutec classifiers,

learn more

Grinding - Hosokawa Alpine

Grinding. Reduce product size to a specific fineness. From pre-crushers for the comminution of coarse materials to jet and ball mills for ultra-fine grinding: Hosokawa Alpine offers mills for a wide range of fineness levels. The mill type that is best suited to your application depends not only on the desired fineness level, but also on which ...

learn more

Ball Mill - an overview ScienceDirect Topics

Mechanical Crushing and Grinding. Oleg D. Neikov, in Handbook of Non-Ferrous Metal Powders, 2009 Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision

learn more

Home Christian Pfeiffer

Hallett Construction Materials assigns Christian Pfeiffer with a sustainable ball mill grinding circuit for its Green Cement Manufacturing plant located in Port Augusta, South Australia. Projects. News. Official dissociation from the cover advertisement of the Russian cement journal "Cement and it's applications".

learn more

Grinding Mills Mineral Processing Equipment CITIC HIC

2023年12月21日 High cost-effectiveness CITIC HIC grinding mills are recognized as China's Manufacturing Industry Single Champion Product. CITIC HIC is responsible for setting the national standards of semi-autogenous mills (SAG mills) and ball mils, supported by powerful database, optimized process technology, cutting-edge design concept, and

learn more

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 Ball mills can grind a wide range of materials, including metals, ceramics, and polymers, and can operate on a variety of scales, from laboratory to industrial (Monov et al. 2013). The produced ...

learn more

Planetary Ball Mill PM 100 - RETSCH - highest fineness

The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 ml sample material per batch. The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization energy and therefore short ...

learn more

Grinding Mill Design Ball Mill Manufacturer - 911

2017年2月20日 Type CHRK is designed for primary autogenous grinding, where the large feed opening requires a hydrostatic trunnion shoe bearing. Small and batch grinding mills, with a diameter of 700 mm and more, are available. These mills are of a special design and described on special request by all Ball Mill Manufacturers.

learn more

Ball Mills - 911 Metallurgist

2017年2月13日 CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density

learn more

Ball mills for various applications Gebr. Pfeiffer

Our ball mills are perfectly suited for the preparation of hard and very abrasive materials. ... In fact we design, build and install ball mills which are specially adapted to grind hard and even extremely abrasive materials.

learn more

polysius® Ball Mill thyssenkrupp Polysius

The proven classical option for cement grinding. Whether employed as a two-compartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding.. Used in combination with the sepol® high-efficiency separator,

learn more

(PDF) Grinding Media in Ball Mills-A Review - ResearchGate

2023年4月23日 The energy con sumption for spherical balls was 3.6 Kw after grinding for 420 minutes, producing a 45µm. residue of 4.37% whilst that of cylpebs was 2.6kW after grinding for 295 minutes producin ...

learn more

Effect of ball mill grinding parameters of hydrated lime

fects of mill charge volume, ball filling and mill speed on the grind-ing power consumption was set at 45 min as a grinding time. The specifications for the grinding media and experimental conditions are presented in Table 2. The energy consumed by the mill in dry grinding experiments of the hydrated lime was measured by a MPR-53S-DIN digital ...

learn more

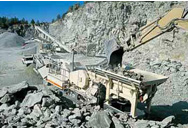

Grinding Mills - Common Types - 911 Metallurgist

2016年11月7日 In Fig. 1.3 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 in. to 108 in., with the corresponding lengths of drum ranging from about 15 in. to 55 in.

learn more

Energetics of collision between grinding media in ball mills

1998年5月15日 In grinding mills used to grind feed materials for several tens of hours, the number of collisions among the balls will be astronomical. Further. ball mills are known to run very warm, with the mill contents heating up to over 2()()~'(" in industrial mills used for batch dry grinding for 20-30 h.

learn more

Ball Mill MIKRONS® Ball Mills

2023年5月25日 Ball Mills are primarily used for single stage fine grinding. It is a key equipment which repulverises the material after it is crushed. It is widely used in manufacturing industries such as cement, silicate, refractory material, fertilizer, glass and all kinds of wet/dry pulverization of ores and other grindable material. MIKRONS Ball Mill ...

learn more

Disturbance observer based multi-variable control of ball mill grinding ...

2009年7月1日 Ball mill grinding circuits are essentially multi-variable systems characterized with couplings, time-varying parameters and time delays. The control schemes in previous literatures, including detuned multi-loop PID control, model predictive control (MPC), robust control, adaptive control, and so on, demonstrate limited abilities in control ball mill

learn more

Grinding Media in Ball Mills-A Review - ResearchGate

2024年1月13日 Table 1. Chemical composition of typical grinding media (% wt.). Adapted from [24]. 2.1.1. Cast Iron Cast iron can be grey cast iron or white cast iron, but white cast irons are commonly used in ...

learn more